QUALITY CONTROL

Our Quality Control (QC) team works closely with the Manufacturing, Quality & Compliance, and Analytical Development / MSAT teams to satisfy our customers, meet regulatory requirements, and ensure successful CGMP manufacturing operations. We remain committed to providing support for the production of high-quality biopharmaceutical products through optimized operating systems and processes.

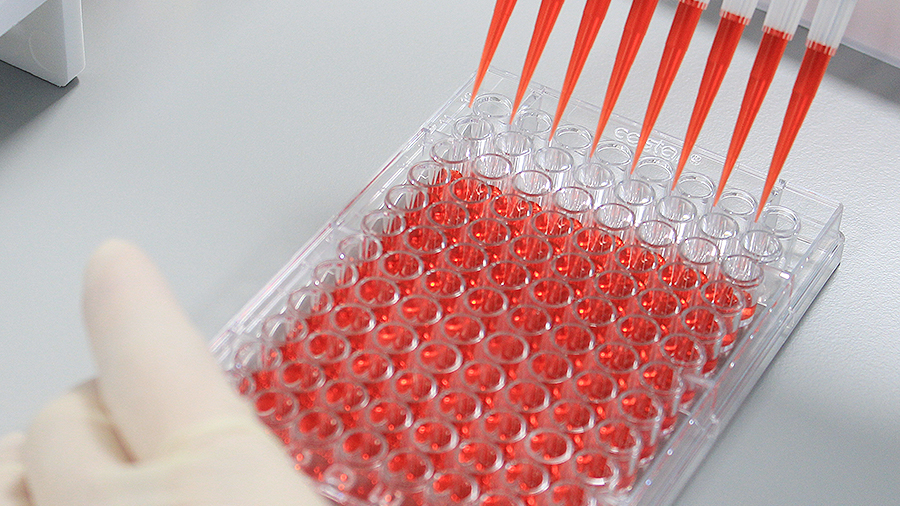

Across the manufacturing process, our QC team performs testing on samples including raw materials, in-process, DS/DP release, and stability. Our QC team is capable of performing analytical test method transfers from client laboratories, method validation, qualification, and verification in accordance to ICH Q2 (R1) guidelines, FDA, EMA, and PMDA requirements.

Our QC scientists provide their expertise based on the extensive experience they have acquired in GMP laboratory environments, and the use of validated cutting-edge equipment. The following are examples of some of the analytical test methods that our QC team is capable of:

- Chemical

Testing -

- 1. Impurity / Purity by HPLC

- 2. Identification by FT-IR

- 3. Water content

- 4. Osmolality, Protein Content (A280), Appearance, pH

- Biochemical

Testing -

- 1. Polymerase Chain Reaction (PCR)

- 2. Enzyme-Linked Immunosorbent Assay (ELISA)

- 3. Electrophoresis (gel-based / capillary electrophoresis)

- 4. Cell-Based Assays

- Microbiological

Testing -

- 1. Sterility

- 2. Microbial Limit (Bioburden)

- 3. Microbial Identification

- 4. Endotoxin

- Biosatefy

Testing -

- 1. In vitro Adventitious virus detection assay

- 2. Mycoplasma detection assay

- 3. Mycoplasma / MVM detection assay by PCR

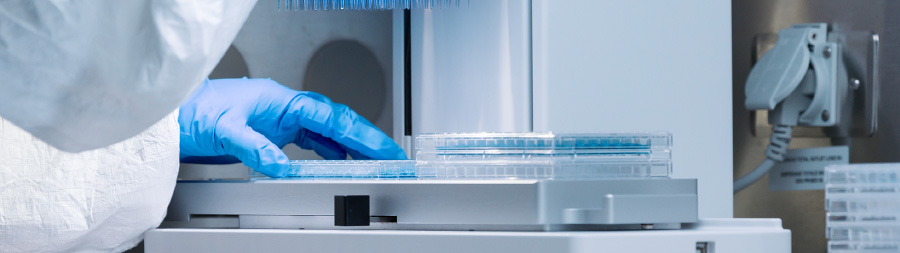

We maintain controlled areas that have validated and monitored stability chambers suitable for the collection of GMP Drug Product/Drug Substance stability data. The physical and kinetic stability profiles are generated with real-time storage conditions and accelerated conditions (with temperature and/or light).

Through our routine testing of facility-related samples (environmental monitoring, water systems, clean steam, clean gas, etc.), QC guarantees that our controlled environments are maintained for the manufacturing of high-quality products. All analyses are performed under strict CGMP requirements. Environmental Monitoring includes the testing for Viable / Non-viable air particles and surfaces. Clean Utilities Monitoring includes the testing of water, compress gases, and clean steam for Bioburden, Endotoxin, TOC, Conductivity, Nitrate, Appearance, and pH.